EtherNet /IP Communication Option Provides Additional I/O

EtherNet /IP customers have been asking Cincinnati Test Systems (CTS) for an add-on input/output (I/O) module for our leak test instruments to provide more system control for some time. With our EtherNet /IP software, additional digital I/O capacity has finally arrived!

EtherNet /IP: More I/O for More Control

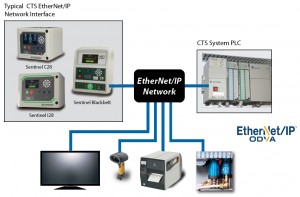

EtherNet /IP functionality allows our Sentinel I28, Blackbelt, C28WE, and C28DP instruments to connect to an Allen Bradley Compact Logix® or Control Logix™ PLC. The PLC, of course, provides the controls the user needs to operate the machine. Our leak test instruments already include numerous I/O connections that allow machine builders to control certain functions (total number of I/O ports varies by model).However, there are times when more I/O is needed to control and monitor all the processes that are required. That’s where the new standard ‘no extra cost’ EtherNet /IP Communications option will not only save you money but also provides additional I/O you may need for communicating with the test system. EtherNet/IP provides a simple plug-and-play communication interface between the PLC and the CTS instrument. EtherNet/IP provides more test instrument I/O; for starters 10 pre-configured inputs and 9 outputs. These fixed inputs and outputs provide common machine function control. Additionally this provides 16 user-defined programmable inputs and outputs. Using EtherNet/IP communications the PLC controls the test system while monitoring the leak test instrument so the PLC knows what the instrument is doing at all times.

In addition to status reporting, EtherNet/IP also relays leak test result summary data, a query of full result measurement information, and other vital data to the PLC. This test system information can be displayed, recorded, and stored for future reference. EtherNet/IP provides a set of fixed, pre-configured I/O points that are built into the program’s structure. These predefined features provide the following functions and capabilities:

| Fixed Pre-Defined Inputs | Fixed Pre-Defined Outputs |

|---|---|

| Start Channel | Instrument Ready |

| Stop | Malfunction |

| Reset | Program Accept |

| Vent/Halt | Program Reject |

| New Reset Clear | New Reset |

| Change Program (with Byte for #) | Requested Reset Available |

| Latch 1 Set | Requested Result Error |

| Latch 1 Clear | Latch State 1 |

| Latch 2 Set | Latch State 2 |

| Latch 2 Clear |

| Available Input Functions | Available Output Functions |

|---|---|

| Start Channel | Malfunction |

| Start Program | Tool Extend 1 |

| Stop/Reset | Tool Extend 2 |

| Hold | Tool Extend 3 |

| Vent/Halt | Tool Extend 4 |

| Program Cal | Tool Extend 5 |

| Open Leak Stud | In Relax |

| Part Present | Program Cal Mode |

| SPC Test Part | Program Cal Master |

| Program Select B1 | Program Cal Leak Standard |

| Program Select B2 | Press Select |

| Program Select B3 | Prefill |

| Program Select B4 | In Fill |

| Program Select B5 | Fill Valve |

| Program Select B6 | In Stabilize |

| Program Select B7 | Isolation Valve |

| Common | In Test |

| Tool Ext Fdbk 1 | Test Passed |

| Tool Ext Fdbk 2 | Test Failed |

| Tool Ext Fdbk 3 | Bellow LL |

| Tool Ext Fdbk 4 | Between Limits |

| Tool Ext Fdbk 5 | Above HL |

| Event Trigger | In Exhaust |

| Ext Press Sw | Program Exhaust |

| Tool Ret Fdbk | Program Reject |

| Tool Ret Fdbk 5 | Server Leak |

| Tool Ret Fdbk 4 | Part Acc Mark |

| Tool Ret Fdbk 3 | Part Rej Mark |

| Tool Ret Fdbk 2 | Tool Retract 5 |

| Tool Ret Fdbk 1 | Tool Retract 4 |

| Tool Retract 3 | |

| Tool Retract 2 | |

| Tool Retract 1 |

EtherNet/IP Easy Installation

[caption id="attachment_42" align="alignright" width="300"] Click Here for EtherNet/IP Details![/caption] With a hardware-based I/O system, the device must be physically installed, which often includes hard wiring individual ports and other difficult, time-consuming processes. But, because it is a software package, installation is fast and easy using standard plug-and-play RJ45 network interface. CTS provides function block Programming with each instrument to establish EtherNet /IP communications between the CTS test instrument and the Allen Bradley PLC. Just a few short minutes are required to set up the program and connect the EtherNet /IP interface and is fully compatible with any Allen-Bradley ControlLogix® or CompactLogix PLC™. The new I/O program can be field retrofitted with existing models of any of the four instruments listed above. CTS leak test instruments with built in EtherNet/IP communications starting in February 2016. For more information, or to order your own EtherNet/IP-enabled leak test instrument,

contact Cincinnati Test Systems today.

Click Here for EtherNet/IP Details![/caption] With a hardware-based I/O system, the device must be physically installed, which often includes hard wiring individual ports and other difficult, time-consuming processes. But, because it is a software package, installation is fast and easy using standard plug-and-play RJ45 network interface. CTS provides function block Programming with each instrument to establish EtherNet /IP communications between the CTS test instrument and the Allen Bradley PLC. Just a few short minutes are required to set up the program and connect the EtherNet /IP interface and is fully compatible with any Allen-Bradley ControlLogix® or CompactLogix PLC™. The new I/O program can be field retrofitted with existing models of any of the four instruments listed above. CTS leak test instruments with built in EtherNet/IP communications starting in February 2016. For more information, or to order your own EtherNet/IP-enabled leak test instrument,

contact Cincinnati Test Systems today.