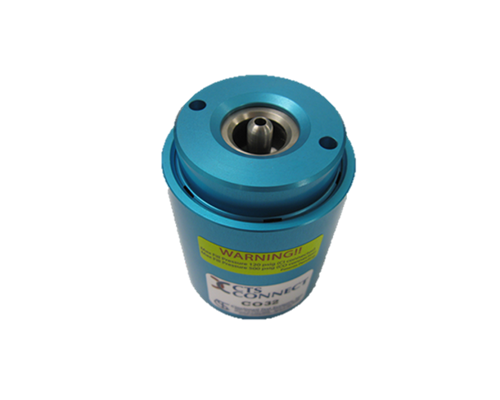

A Tight Seal Every Time with CTS Custom Connectors and Seals

Using our CTS Connect® line, we offer a wide variety of custom and specialty solutions to ensure the best seal for your application, including designs to accommodate non-round, irregular-shaped ports, and custom face sealing designs to accommodate inconsistently shaped test parts and components. We offer solutions for OD (outer diameter) and ID (inner diameter) sealing, with pneumatic and manual options.We work with you to determine what you need—and make it quick and easy to implement. Delivery time on custom connectors and seals is generally 5-6 weeks, with expediting options available, as possible.

Long-lasting Custom Designed Connectors and Seals

There are a variety of reasons manufacturers require custom leak test connectors and seals. It could be a clearance issue; the part you’re trying to seal doesn’t have enough clearance around the port for a standard connector to fit securely around it. It could be a sizing issue, where the area of the part where the connector needs to be placed is too long/short or too wide/narrow for a standard connector. It could also be due to irregularly-shaped ports.

No matter the problem, CTS Connect® offers a solution with custom connectors and seals. We work with you to determine why a standard part isn’t working and devise a solution. Depending on the situation, we can make modifications to our standard parts, or design and manufacture wholly unique designs to suit your needs.

Below are some examples of the customizations we employ to get you the right fit.

Custom Face Sealing Designs

Custom face sealing designs, with custom-shaped front nose piece cradles, are often used to seal non-round, irregular shapes. These designs capture and hold the part in place, enabling the seal to grip behind a larger end piece. The seal is mechanically held and fixed in place to provide a reliable seal that won’t pop off during test. This is a good solution, whether you are sealing an irregular shape, or the part you are sealing has a bulge or flare diameter at the end of the component.

Dual ID and OD Sealing Applications

We offer customized sealing options for ID and OD applications that require dual sealing in the same test location. This could be an application that requires multiple sealing points along the same vertical, or multiple sealing points side by side. These sealing points can also be varying sizes. We will work with you to create a custom solution to meet your needs.

Custom Face Sealing Designs

Custom face sealing designs, with custom-shaped front nose piece cradles, are often used to seal non-round, irregular shapes. These designs capture and hold the part in place, enabling the seal to grip behind a larger end piece. The seal is mechanically held and fixed in place to provide a reliable seal that won’t pop off during test. This is a good solution, whether you are sealing an irregular shape, or the part you are sealing has a bulge or flare diameter at the end of the component.

Sealing flexible hoses and tubes

A test application we see in the medical industry in particular is the requirement to seal on the outside diameter of a flexible hose, which poses challenges. To ensure a tight, reliable seal, we used a stainless insert to support the internal diameter of the hose to prevent it from collapsing during test.

Sealing behind a bead or tube form

This design employs a custom stainless spring latch mechanism to secure behind a bead or form on a tube end while sealing on the OD of the part. This is a fairly common application we see across a variety of industries, with each aspect of the design able to be customized to meet the exact specifications of your parts.

Trusted and Durable: Use Custom-Designed Connectors and Seals from Cincinnati Test Systems

Superior sealing materials make CTS custom connectors and seals last longer than the competition. We offer a wide variety of options and sizes to make sure you get the right fit for your needs.

Looking for custom leak test connectors and seals for your production line?