Rely on our team of technical experts and uniquely broad range of leak test instruments for your electric vehicle application.

Planes, Trains, and Automobiles:

We are Leak Test for eMobility

We are Leak Test for eMobility

Leak Testing for eMobility Components

Challenges related to leak testing new components being manufactured in the e-mobility industry are why companies contact Cincinnati Test Systems. These challenges are not new to us: we’ve been supplying testing solutions to manufacturing companies for over 40 years. With every new product comes a range of problems that CTS has helped other companies address for leak testing their components, sub-assemblies, and final assemblies.

At CTS there is a team of technical experts who will listen to your challenges and use a wide range of leak testing experience to help you understand the differences between measurable testing techniques, operator dependent techniques, and suggest the right direction for your unique application. The key to this level of support is that CTS supplies every measurable testing technology on the market, allowing manufacturers to remove operator error and focus on cost effective testing methods that meet their cycle time expectations and their budgets.

Our team has been supporting eMobility testing from the very beginning helping companies move from R&D prototype testing to production testing.

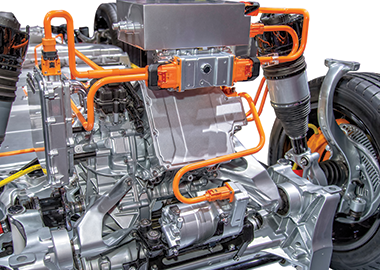

Solutions for Leak Testing Electric Vehicle Assemblies

You can rely on CTS for leak detection solutions for testing a range of eMobility components. Browse some examples below.

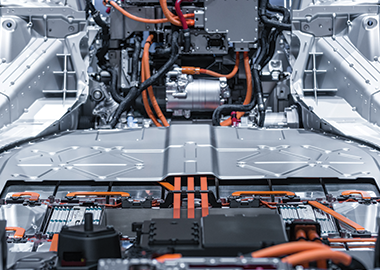

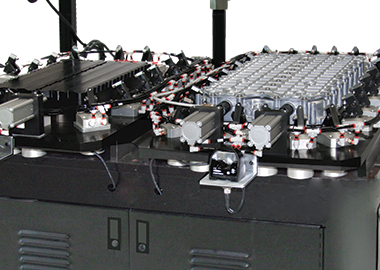

Battery Assemblies & Sub-assemblies

Cooling circuits & plates, cells, modules, covers, trays and packs: we offer a range of instruments and solutions for leak testing batteries.

Inverters and Drive Housings

Porosity in castings adds a level of difficulty when conducting leak testing these assemblies. CTS offers special techniques for these types of components.

Electronic Components

Parts such as lights, cameras and electrical connectors are often tested to meet the water tightness indicated by IP ratings.

Coolant Systems

Utilize helium accumulation leak testing to meet production throughput requirements with repeatable measurement results.

Sequentially Testing Die Cast Part Chambers

Battery enclosures with cooling circuits require independent testing to verify that cooling passageways do not leak fluid into the enclosure chamber.

The Largest Variety of eMobility Testing Solutions

CTS supplies leak testing solutions for the eMobility industry offering the largest selection of technologies and instruments to support each. CTS leak test instruments offer more value-added features than any others on the market. Our leak detection equipment uses standard testing capabilities from basic pressure decay and mass flow technologies to tracer gas technologies.

The solution to your leak testing needs is selected based on your test specifications and production through-put requirements. A CTS team member will work through the application requirements and help guide a solution based on real world experience while identifying the most appropriate technology for the application. Since CTS can supply any and all available measurable technologies, there are no biases related to the suggested solution, it is based on the most effective and efficient technical solution for your application.

Testing equipment and leak test accessories from CTS are used by eMobility manufacturers around the world. Wherever you are, CTS products can help you ensure that your products adhere to the leak standard requirements required for the specific applications.

Ingress Leak Testing for Electric Vehicle Components

Learn how to choose the right technologies and methods for leak testing water-tight EV assemblies such as batteries, drive units, charge station components and more.

Technologies that CTS utilizes for EV Components

The CTS technical sales and application engineering team can help advise your team with technical understanding related to each of the measurable leak test technologies on the market today. With this understanding you will be able to choose the best fit for each of your production testing programs. To choose the best technology, we will discuss expected production rates, leak rate specification, test pressure, part volume (size), part sealing locations, production line requirements, and part handling for load/unload at the test cell.

CTS has more than one technology to support eMobility testing applications.

Mass Flow

- Leak test

- Functional flow test

- Blockage flow test

Trace Gas

- Sniff test for leak location

- Accumulation test

- Nitrogen purge leak test

- Hard vacuum Helium mass spectrometer leak test

Pressure and Vacuum Decay

- Pressure drop over time

- Calibrated leak rate

- Differential pressure decay

- Back pressure measurement for blockage (occlusion test)

Talk to a Leak Test Expert

We provide a range of eMobility leak testing solutions to meet your specialized needs. Contact us to learn more about our testing technologies for your standard and custom testing equipment.