Function Testing Truck Turbo Actuators

Problem:

The manufacturer of truck turbo systems performs several function tests on the turbo actuator to verify product performance. The turbo actuator adjusts the amount of boost provided by a turbo in a truck engine. This Smart Actuator with on-board processor communicates through CAN communications to the truck’s engine.

Test Requirement:

Response Test: Checks the speed of the actuator moving to the open position and to the closed position.

Position Accuracy Test: Checks the device’s accuracy when moving to and holding at defined locations.

Fail Safe Test: Checks to make sure the unit will move to an off state position in the event of a power failure.

Seating Torque: Verifies the unit can produce a minimum amount of torque.

Internal Check: Communicates with the on-board processor to verify that registers are set to the correct values and for any internal error codes.

CTS Solution:

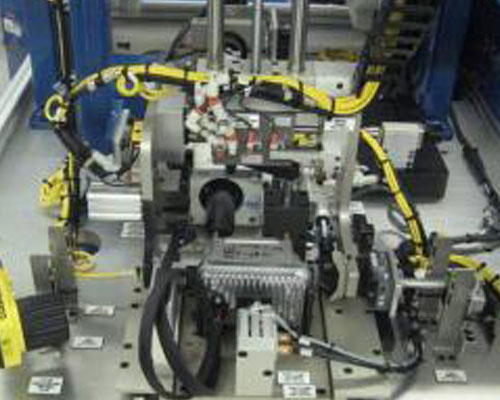

Cincinnati Test Systems developed a single station test stand with an auto-unload conveyor for rejected parts. The system also includes the following features:- Accepted parts are marked by a Pin stamp with the Julian date code and serial number.

- Dual reject lanes on an indexing reject conveyor protects parts and segregates the rejected parts.

- Adjustable actuator arm torque system capable of holding a preset torque during motion and non-motion of the actuator arm.

- Hybrid controls system using Lab View and an Allen-Bradley PLC.

The Result:

The manufacturer is very pleased with the stand’s performance and is considering purchasing more.

Contact CTS

To Discuss Your Leak Detection System Requirements

Contact CTS

Contact Cincinnati Test Systems to learn more about our leak detection equipment

Contact UsCustomer Login

An account is needed to view restricted documents such as user manuals and to submit RFQ requests.

Sign In