Leak Testing Cardiovascular Devices

CTS delivers the right sealing, precise pressure, and ideal sensitivity to ensure accurate test results for cardiovascular medical devices.

Cardiovascular disease is the leading cause of death worldwide. However, innovative treatments with new designs and materials are continually improving patient care. Cincinnati Test Systems helps medical device manufacturers save lives with our leak test solutions for disposable cardiovascular devices such as catheters and vascular access blockage sheaths.

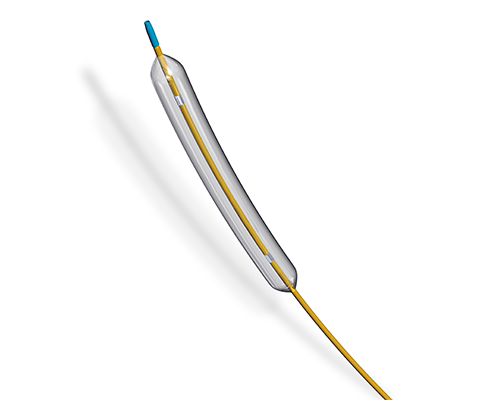

Leak Testing Non-Compliant Balloon Catheters

Non-compliant balloon catheters are ideal for applications where the balloon must expand to a specific diameter with a specific high pressure to address a blockage, dilation, or stent delivery. They are equipped with an inflatable balloon near the distal or outlet of the device. Typically made of polyester/PET or nylon, they are capable of inflating to a specific diameter at relatively high saline or radiopaque solution injection pressures.

The type of test method is dependent on the type of non-compliant balloon catheter. For those that are non-stented, most applications use pressure decay testing positive pressures ranging from 150 psig to 450 psig. Stented versions use either vacuum or very low positive pressures between -12 psig to +10 psig to prevent deforming the stent during the test. Standard, single-channel Sentinel Blackbelt or the multi-channel Blackbelt Pro pressure decay instrumentation can be used for these tests.

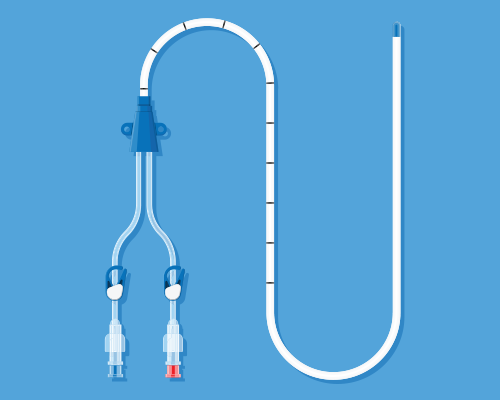

Testing Multi-Lumen Catheters for Leaks and Blockages

Multi-lumen catheters are ideal for many different applications, including highly complicated procedures. As such, they are often designed with a wide range of performance characteristics that have specific leak and blockage test requirements.

This type of catheter has a single tube with multiple internal pathways/lumens (tubes within a tube) isolated from one another. It permits external access of media to each lumen individually, typically without cross-contact with any other pathway inside the catheter. Often these are used for exchange of blood or to permit drug/solution delivery within the vasculature of the patient.

Most catheters are tested after final assembly: they are tipped and have skived holes cut radially on the outside diameter of the multi-lumen shaft at the distal end of the catheter. Others are tested prior to finishing when untipped and before any skived holes have been cut.

Leak testing either configuration requires a two-step process to first find leaks and then determine whether there are blockages. A single Sentinel Blackbelt instrument can perform both tests in production. Read the application bulletin to learn more.

Leak testing either configuration requires a two-step process to first find leaks and then determine whether there are blockages. A single Sentinel Blackbelt instrument can perform both tests in production. Read the application bulletin to learn more.

Leak and Occlusion Testing of Access Sheaths

Vascular access sheaths, also known as sheath introducers, are used to introduce catheters, stents and other interventional devices into blood vessels. Commonly used in catheter-based,

minimally invasive procedures, this device acts as a hemostasis (blood-blocking) access port where catheters and guidewires may be placed/threaded into the patient’s vasculature with minimal blood loss.

The proximal end of the sheath typically has a molded and slit elastomer aperture that self-seals around catheters and guidewires after they are placed inside the patient.

The majority have a flush port mated to the side of the device which is a manual stopcock attached to a tube mated to the side of the sheath. It allows the clinician to connect a saline-filled syringe to the stopcock, open the stopcock and use the syringe to both expel any air from the interior of the sheath prior to placement into the patient or to expel blood back into the vasculature just prior to removal of the sheath from the patient near the conclusion of the procedure.

Tests are conducted to inspect for leaks and potential blockages on 100% of parts during production. The potential exists for the adhesive bond between the flush port tube and either the stopcock or the sheath to be completely or near-completely blocked should excess adhesive be applied. As such, most manufacturers execute a basic “inverted-limit” pressure decay test to verify patency from the interior of the sheath all the way out through the stopcock.