Leak Testing Diagnostic Sets

Cincinnati Test Systems offers the most accurate leak testing solutions for diagnostic applications like microfluidic chips and reagent cartridges.

Patients rely on the accuracy of the diagnostic equipment medical professionals use. With limited biological samples, laboratory test equipment needs to get it right the first time. Cincinnati Test Systems delivers leak testing solutions that detect production problems or assembly failures before the products are released to market. Leak tests can be conducted on every component in the assembly line, so you know the devices meet specification every time.

Leak Testing Reagent Cartridges

Reagent cartridges are small diagnostic tools ideal for point-of-care applications. They contain substances or compounds used to initiate a chemical reaction when exposed to a bio-media. They are most often used for the purposes of infection verification or genetic determination by automated and semi-automated diagnostic (IVD) testing, gene sequencing, and micro-array scanning instrumentation/analyzers. Such devices are commonly found in larger bio-labs or point-of-care facilities such as hospitals or clinics.

Because of the critical nature of reagent cassettes, it is important to conduct leak tests on 100% of these components during production to inspect for leaks within either empty or filled cartridges.

You Want to Test 100% of Diagnostic Devices Without Slowing Assembly? No Problem.

Contact us for reliable, automated tests that deliver accurate results while meeting your production goals.

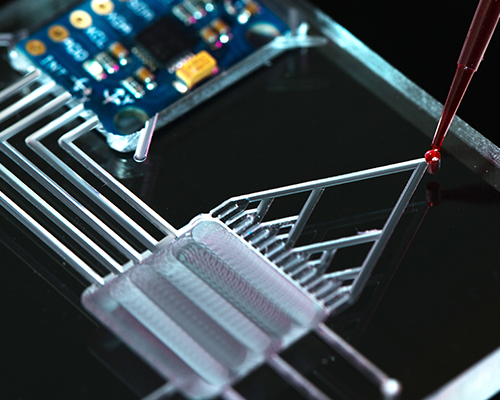

Leak and Blockage Detection of Microfluidic Chips

Microfluidic chips are small devices that can handle very small amounts of fluid, which allows a small sample consumption, lower cost of biological analysis, and a better reaction rate. They are used in many types of biological diagnostic applications, such as analytical separation, detection, and fluid control (sampling/mixing). Once placed within durable analytical instrumentation, these devices typically have multiple unique micro pathways isolated from one another for liquid media passage, sampling, and analysis.

The manufacturing process for microfluidic cartridges uses injection-molded polymer layers which are laminated, or bonded, together to form tiny, sealed pathways for liquid media passage. These pathways are sometimes only a few microns wide and deep.

As liquid flow control is paramount to the functionality of these devices, assembly failures due to either leakage or blockage must be detected in production. These devices commonly require a two-step process to detect both leaks and potential blockages on each unique microfluidic pathway within each chip. Read the application bulletin to learn more.