Volumetric Fill Leak Testing for Sealed Parts

Volumetric fill leak testing is the first of a two-step process for use on sealed devices. As sealed parts do not have ports to apply pressure or vacuum to test for leaks, conventional pressure or vacuum decay testing won’t work. The volumetric fill test ensures there are no gross leaks in the part prior to conducting the fine decay leak test. Without it, you could fill up the volume of a gross leaking part during the fill stage of the test and never be able to check for a small leak as there wouldn’t be an air pressure differential on the part chamber.

Benefits of the Volumetric Fill Leak Test

- Provides a dry and non-destructive leak test

- Provides sensitivity to detect very small leaks

- Provides protection from over-pressurization

- Leak test parts to IP67 ingress contamination standards

- Can test in pressure or vacuum environments

Perform Both Gross and Fine Leak Tests with the Same Sentinel I28 Instrument

The process for sealed devices has two steps and a Sentinel I28 can handle them both.

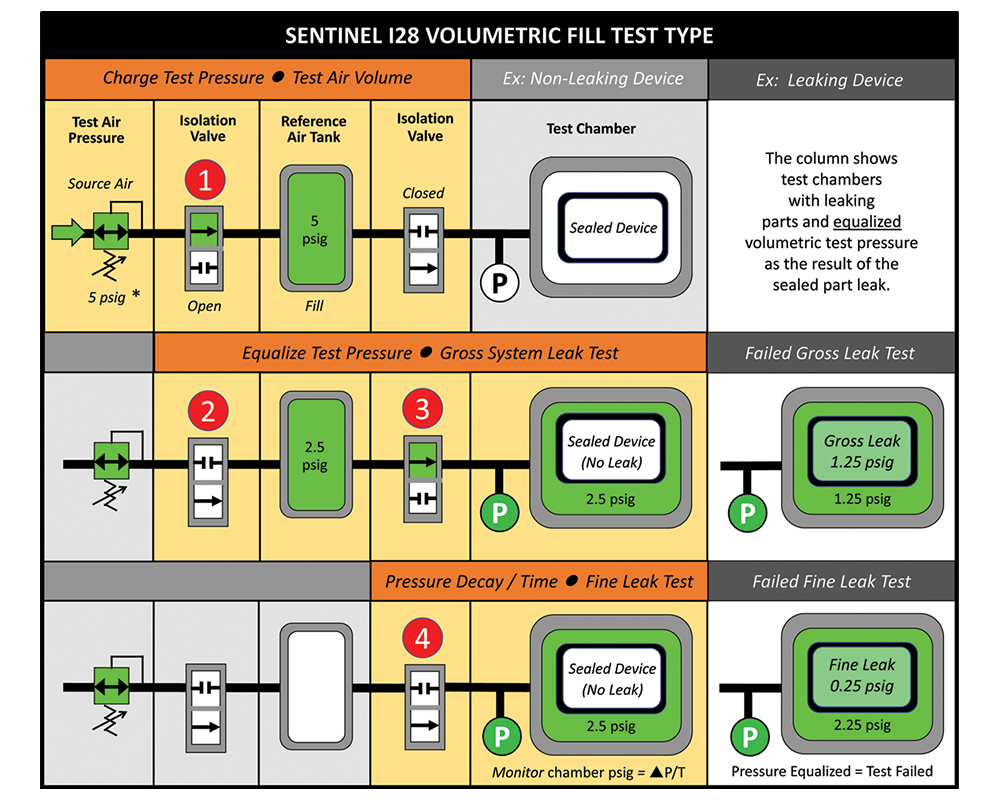

Volumetric Fill Leak Test Method

The volumetric fill test, the gross leak test, will make sure there are no gross leaks in the part prior to conducting the fine decay leak test. To test a sealed part the part is placed inside a sealed chamber and the leak test is conducted on the air or space inside the chamber surrounding the outside of the part and test for air being forced inside the part or for air to escape the part.

The Volumetric Fill introduces a known reference volume into the test circuit and uses equalization of a known pressure to accurately measure the leak. If the part has a gross leak the test would not meet ‘target pressure window’ specification and fail the gross leak test. If the passes the gross leak test the program automatically performs the fine pressure decay leak test.

Imagine the volume of your reference air tank being the same of the volume of the free space of the chamber surrounding the outside of the part and neglect all the tubing and inefficiencies. If the reference volume, example 5 psig, is allowed to flow into the test chamber with a good part then the equalized pressure would be around 2.5 psig. If there was a gross leak in the part and the part was the same volume as the reference tank, then the new pressure would be 01.25 psig and the test would fail. If the part passes the gross leak test a ‘fine’ pressure decay leak test is performed on the part.

For details on the fine pressure or vacuum decay leak test, see the absolute Pressure Decay - dP and dP/dT page.

Contact CTS

To Discuss Your Leak Detection System Requirements

Contact CTS

Contact Cincinnati Test Systems to learn more about our leak detection equipment

Contact UsCustomer Login

An account is needed to view restricted documents such as user manuals and to submit RFQ requests.

Sign In