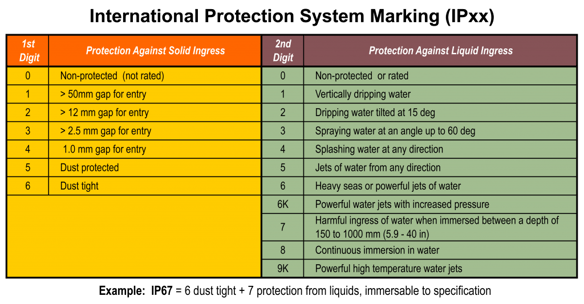

IP67, IP68 & Other IPxx Product Designations IPxx designation can be applied to any industrial or consumer product that has been tested for resistance to ingress. Ingress contamination is typically tested using air pressure or vacuum to simulate the physical environmental conditions to which the product in question will be exposed in everyday use. Implementing leak testing, such as for IP6x, IP67, or IP68 certifications, into your manufacturing processes can help identify:

IP67, IP68 & Other IPxx Product Designations IPxx designation can be applied to any industrial or consumer product that has been tested for resistance to ingress. Ingress contamination is typically tested using air pressure or vacuum to simulate the physical environmental conditions to which the product in question will be exposed in everyday use. Implementing leak testing, such as for IP6x, IP67, or IP68 certifications, into your manufacturing processes can help identify:

- How well your product performs and functions as designed to ingress standards for dust, water, and other fluids

- Product performance or quality issues

- Ways to reduce waste/scrap

- Methods for improving product reliability while reducing liability

- Process control validations via test results

CTS’ Advanced IPxx Leak Testing Solutions Cincinnati Test Systems’ leak test solutions are used by manufacturers all over the world to address ingress contamination in automotive, medical, energy, military, transportation, and consumer products. CTS offers turnkey designs and applications support that will meet or exceed your objectives and performance expectations. Our IPxx leak test solutions include function testing, performance testing, and a broad range of leak test methods utilizing pressure decay, vacuum decay, differential pressure decay, volumetric fill, mass flow, and tracer gas technologies. Implementing CTS ingress contamination test equipment into your process environment will help you determine how well your product will perform relative to its intended specification. CTS leak test units include capabilities to simulate exposure to dust, dirt, condensation, and liquids, and are the perfect way to ensure conformance to IPxx ingress contamination requirements. Contact us today to have our experts review your application with you to see how CTS test equipment can benefit your next project!